——

Clamping components by computer simulation,the overall optimization from the kinematic and dynamic characteristics,using the technology-leading five-point double toggle oblique clamping,template by finite element analysis,innovation of the hollow spherical structure of the head board,plywood box frame steucture and templates,siamese,etc.To ensure mold parts is high rigidity and high reliability,to achieve a smooth opening and closing mold,mode-locked solid,large distance between the lever mold can be installed.

> Mechanic,electronic & hydraulic triple interlock safety protection function

> Multiple stages control for mold opening clamping pressure,speed,posotioning control

> Sensitive low-pressure mold protection device-eject

> Hydraulic motor-driving gear mold adjustment

——

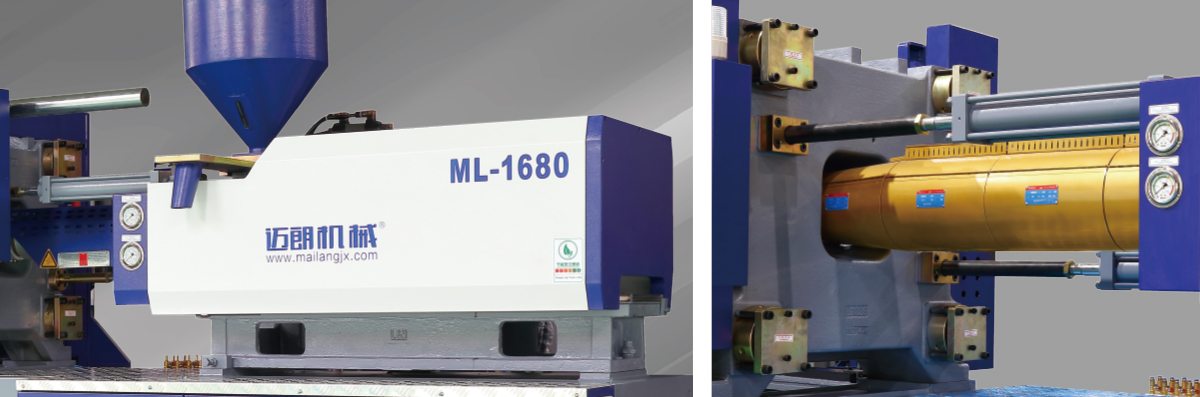

Injection components use dual-cylinder balance injection unit and duble-leaders direct line rail supporting.A rich special screw libray can be choose customers and can be fitted with a variety of injection molding.Furthermore,the be compatible with a variety of special injection devices,convenient for customers.They use high-performance low-speed torque hydraulic motor directly driving a large pre-plastic screw.

There are several screws and barrels with optimal design,Respectively,nitride,hard chromium plating,dual-metal,which is suitable for different plastic material’s request.

The high-torque hydraulic motors offer a stable plasticizing capacity,high-precision Linear transdurer device position detection enable accurate measurement.

Multi-injection speed and pressure and multistaye pressure setting,switch from the injection time,location,pressure control to ensure the quality of molding.

——

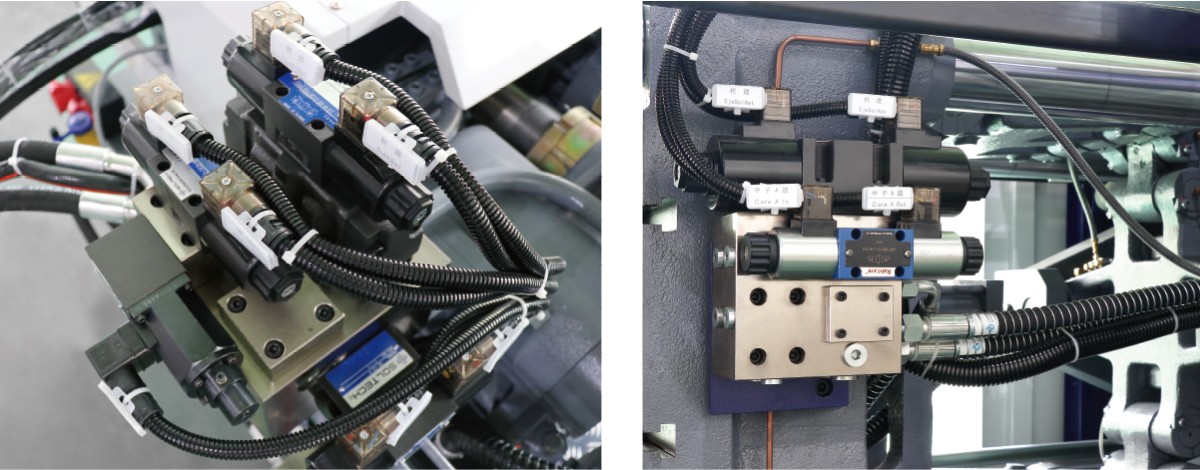

Based on the hydraulic system of MAILANG modular design, we can easily solve the problem for you, whether it is the precise energy-saving technology or the multi-synchronous action for the high efficiency production.

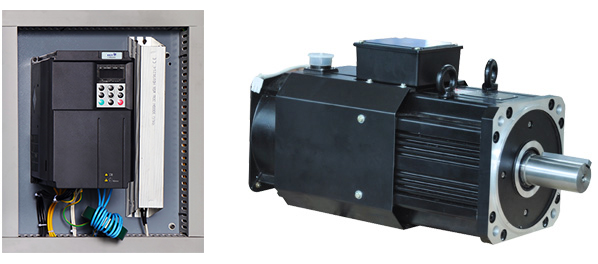

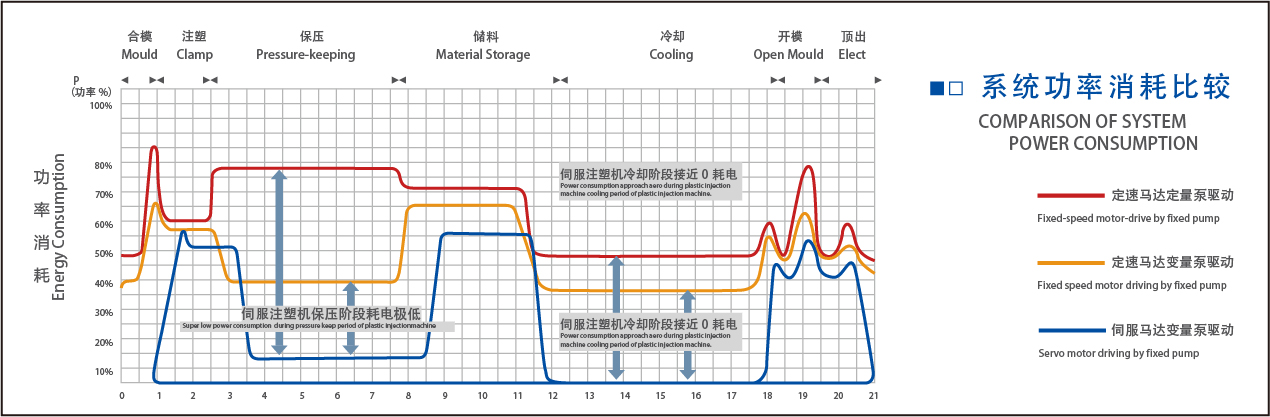

Energy saving:Standard with precision and energy saving servo power system, the output drive system is sensitively altered, according to the actual need of the plastic parts being produced, avoid energy waste. Depending on the plastic parts being produced and the material being processed, energy-saving ability can reach to 20%~80%.

Environmental protection:The machine is running low noise, low power consumption; European Famous hydraulic hose, using the DIN standard spherical joints, valve plate with G thread sealing plug, to prevent oil pollution.

Convenient: Visible and dischargeable oil tank, easy for hydraulic circuit maintenance, self-seal suction filter, reasonable placed hydraulic pipe fittings, maintenance will be easy and convenient.

——

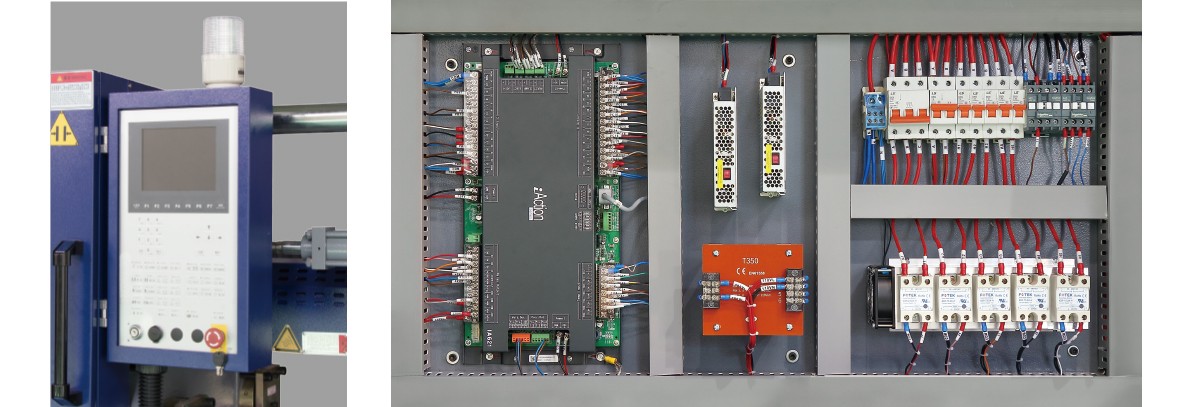

Stable and reliable hardware: Adopt world first-class hardware and production testing technology, ensure its stable and reliable quality, IO short circuit protection function, more safety for using;All of product passed CE certificate, stable hardware performance reduced your maintenance and service cost.

Excellent control software: Controlling software is very advanced and excellent, ensure machine movement stable and precise, we support the functions like: machine automatic adjustment, mold data automatic memory (easyMold), and optimized temp PID control functions etc.

User-friendly menu design:New designed user-friendly operation menu, it will make you feel “machine operation is so easy”

——

Excellent Molding Stability

The servo driving system has its pressure and flow under closed loop control; and com pared with traditional injection molders, its molding repetition precision is improved substan tially

Constant Oil Temperature

The servo motor output hydraulic oil proportionately to prevent excessive heat. It can achieve substantial water saving even without cooling.

Rapid Response

The servo driver features rapid response whose rapid starting time is improved by 50% com pared with traditional injection.

Substantial Energy Saving

Under the same conditions, it can save 20%-80% energy compared with traditional con stant delivery pump injection molders.

High Performance Environmental Protection

The complete machine features low operating noise, and even quieter during low-speed oper ation